| Profile roofing sheets

Profiled Roofing Sheets

Profiled Roofing Sheets are a versatile building material made from galvanized steel with a polymer coating. Thanks to their shape (profile), the sheets gain high rigidity, allowing them to withstand significant loads.

Unlike standing seam roofing, profiled sheeting is a self-supporting material (regulated by standard EN 508-1). This means it does not require a solid deck and can be installed directly onto purlins or spaced battens, making it a cost-effective solution for large-span buildings.

Profiled sheeting is widely used for the construction of roofs for workshops, warehouses, commercial pavilions, and hangars.

Key Advantages

- Cost-effective: Low cost of material and installation, minimal maintenance expenses.

- Simple and fast installation: Large sheets quickly cover a significant area.

- Lightweight: Does not place a significant load on the building's structural frame.

- Durability: Reliable protection thanks to galvanization and modern polymer coatings (Ruv4, RC3/RC4).

- Versatility: Widely used for various types of roofing applications.

Main Applications

While standing seam roofing is often chosen for its water tightness on low slopes, and metal tiles for their aesthetics, profiled sheeting is the most practical and cost-effective solution for the following roofing tasks:

- Industrial and commercial buildings: Thanks to its high load-bearing capacity (especially AP-45) and cost-effectiveness, profiled sheeting is the standard solution for the roofs of workshops, warehouses, hangars, and shopping centers with long spans.

- Utility buildings and simple roofs: Its low weight, ease of installation, and affordable price make profiled sheeting (especially AP-20) an ideal choice for garages, canopies, garden sheds, and other structures with simple gable or lean-to roofs.

- Renovation of old roofs: The lightness of the material allows it, in some cases, to be installed over an old roofing cover (like roofing felt), which significantly speeds up and reduces the cost of repair.

Profile Types

We produce three main types of profiled sheets, which differ in wave height and, consequently, in load-bearing capacity.

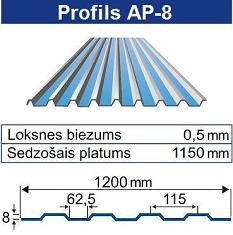

AP-8: A low profile (8 mm), typically used for roofing on small utility buildings or canopies.

AP-20: A universal roofing profile (17.5 mm), optimal for private homes and commercial buildings.

AP-45: A load-bearing profile (42 mm), used for roofs with long spans and high snow loads.

Technical Specifications

The main technical parameters of the profiles we manufacture:

| Characteristic |

AP-8 |

AP-20 (A/B) |

AP-45 |

| Profile Height |

8 mm |

17.5 mm |

42 mm |

| Total Sheet Width |

1200 mm |

1160 mm |

1090 mm |

| Covering (Effective) Width |

1150 mm |

1100 mm |

1020 mm |

| Recommended Steel Thickness |

0.5 mm |

0.5 – 0.7 mm |

0.5 mm (and up) |

Available Materials and Coatings

Profiled sheeting is produced from the same high-quality steel as other roofing materials, ensuring durability and corrosion resistance.

| Material |

Description |

| Galvanized Steel (Z275 g/m²) |

A basic, economical option, often used for industrial or temporary buildings. |

| Coated Steel (PE, HDP, PVDF) |

The optimal solution for roofing, combining protection (RC3/RC4, Ruv4) and aesthetics. |

For coated materials, a selection is available from the color catalog.

Fastening Technology

Unlike standing seam roofing, profiled sheeting uses an exposed (through-fastened) system. The sheets are installed overlapping each other (usually by one corrugation).

Fastening to the substrate (battens or purlins) is done with special roofing screws fitted with an EPDM washer, which seals the hole. The screws are driven into the lower part of the wave (the valley) to ensure a tight fit against the substrate.

Substrate Requirements

Profiled sheeting is a self-supporting material and does not require a solid deck (like standing seam or bitumen shingles). It is installed on spaced battens (for wooden structures) or metal purlins (for hangars and workshops).

The batten spacing (distance between support points) depends directly on the profile type (the higher the wave, the wider the span) and the calculated snow and wind loads for your region.

Installation and Repair

SIA "Akvilon" provides fast and professional installation of profiled roofing, and also carries out repair work to replace old roofing materials.

We offer a full range of services — from accurate calculation of the required number of sheets and flashing to high-quality installation.

Roofing Components

For a finished look and proper functionality, profiled roofing requires additional components. We also produce:

- Flashing components: Ridges, verges, abutments, and valleys, made from the same material as the main roof.

- Rainwater systems: Round and square systems for effective water drainage.

- Fasteners: We will help you select the correct roofing screws with EPDM washers to match your roof color.

Calculation and Kitting

We are ready to help with calculating the required amount of profiled sheeting for your roof, as well as with selecting all components and fasteners. Contact us to get a full specification and consultation.

| |

|

|