Metal Roof Tiles

Metal roof tiles are profiled sheets of galvanized steel with a polymer coating, which are stamped on special equipment to get a pattern imitating natural ceramic tiles. Today, this is one of the most popular types of roofing for private home construction.

The material combines the aesthetics of classic tiles with the lightness and durability of metal. It is regulated by the European standard EN 14782 (like standing seam), which defines the requirements for self-supporting metal sheets for roofing.

Metal roof tiles are ideal for all types of pitched roofs with a slope of **at least 15 degrees**.

Key Advantages

- Aesthetic Look: Accurately imitates classic ceramic tiling.

- Lightweight: Low structural weight (approx. 5 kg/m²) does not put a heavy load on the rafter system.

- Ease of Installation: Sheets are installed quickly and easily, unlike individual ceramic tiles.

- Durability: High resistance to corrosion and color fading thanks to the multi-layer protective coating.

- Eco-friendly: A safe, environmentally friendly material.

Technical Specifications

We offer the classic and most in-demand metal tile profile with optimal parameters.

| Characteristic |

Value |

| Transverse wave pitch |

350 mm |

| Profile height |

24 mm |

| Total sheet width |

1180 mm |

| Covering (effective) width |

1100 mm |

| Steel thickness |

0.5 mm |

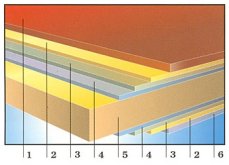

Protective Coating Structure

The raw material for metal roof tiles is high-quality steel, which undergoes a complex technological process to ensure maximum durability:

- Polymer coating (PE, HDP, PVDF): The top layer, responsible for color and protection against UV radiation (Ruv4) and scratches.

- Primer: Ensures ideal adhesion between the polymer and the metal.

- Anti-corrosion coating: A phosphate layer that passivates the surface.

- Zinc coating (Z275 g/m²): The main protective barrier against corrosion.

- Steel sheet: The base material (usually 0.5 mm).

- Protective lacquer: Coats the reverse side of the sheet for protection against condensation.

As a result, the material is resistant to sunlight and temperature fluctuations.

For coated materials, a selection is available from the color catalog.

Fastening Technology

Metal roof tiles, like profiled sheeting, use an exposed (through-fastened) system. The sheets are installed with an overlap.

Fastening to the battens is done with special roofing screws fitted with an EPDM washer in the roof's color. Unlike profiled sheeting, the screws are driven **into the valley (the low part of the wave)**, which rests against the batten, strictly under the step.

Substrate Requirements

Metal roof tiles are installed on standard spaced battens made of dry, treated timber. The batten spacing is a critical parameter and must strictly correspond to the transverse wave pitch of the profile — **350 mm**.

Installation and Repair

SIA "Akvilon" provides fast and professional installation of metal roof tiles, and also carries out repair work to replace old roofs.

Roofing Components

To give your home a finished look, SIA "Akvilon" produces all the necessary roofing flashing (ridges, drips, eaves, verges, etc.), as well as rainwater systems.

Maintenance and Care

Metal roof tiles are one of the lowest-maintenance materials, but minimal care will help maximize their lifespan:

- Cleaning: It is recommended to inspect the roof once a year (usually in spring) and clean gutters of leaves and debris. The roof surface itself can be washed with water (not high pressure) to remove dust.

- Fastener Inspection: During cleaning, visually inspect the screws to ensure the EPDM washers have not dried out and are still snug.

- Touch-up Scratches: If deep scratches (down to the metal) appear during installation or snow removal, they should be immediately treated with special touch-up paint to prevent corrosion.

Calculation and Kitting

We are ready to help with calculating the required amount of metal roof tile sheets for your roof, as well as with selecting all components and fasteners. Contact us to get a full specification and consultation.