Insulated Stainless Steel Chimneys. General Overview

IZOKOMPAKT is a high-quality insulated (double-wall) chimney system made of heat-resistant and acid-resistant stainless steel, grades AISI 304L/316L. The construction consists of an inner liner (a stainless steel sheet with a thickness of 0.6 mm to 1.2 mm, EN 1.4404/EN 1.4301), a 50 mm thick insulation layer (fire-resistant basalt wool with a working temperature of up to 1000°C), and an outer casing. The outer casing can be made of stainless steel, galvanized steel, or a painted sheet with a polymer coating (PE), with the color chosen by the customer from a catalog. For special aesthetic requirements, the NordicPipe premium version is available, featuring a stylish matte black powder-coated finish.

The IZOKOMPAKT insulated chimney system is suitable for all heating appliances that burn solid fuel (stoves, fireplaces, cookers, sauna heaters, solid fuel boilers), as well as central heating boilers (standard gas, oil, solid fuel, and pellet).

The chimney system, produced by SIA Akvilon, is certified, CE marked, and complies with the mandatory LVS EN-1856-1 standard requirements in Latvia and the EU. Only certified and tested materials are used in its production.

Go to the product catalog (IZOKOMPAKT & NordicPipe) →

Advantages

- The circular cross-section of the metal chimney ensures better draft, and thanks to the rapid heating of the stainless steel, a stable draft is established almost immediately after starting the heating appliance.

- Easy and fast assembly. A wide selection of connecting elements allows for the installation of systems of any complexity and helps to efficiently manage condensate drainage and chimney cleaning.

- Lightweight construction. Due to its low weight, the system does not require a special foundation and can be installed on any floor of the building.

- High resistance to high temperatures and acidic condensate.

- The perfectly smooth inner surface of the pipe prevents soot accumulation.

- Aesthetic appearance and the option to paint the outer casing in any color from the RAL catalog.

General Installation Overview

The proper installation of an insulated chimney system is the foundation for the safe, efficient, and long-lasting operation of the heating equipment. The system is a modular construction of double-wall elements, which ensures its quick assembly and versatility. Insulated chimneys can be installed both inside and outside a building, allowing for the creation of new flue channels in existing houses without major construction work.

The chimney's construction consists of an inner stainless steel liner, a 50 mm thick layer of non-combustible rock wool insulation, and an outer protective casing. This sandwich construction solves several problems at once: the insulation maintains a high flue gas temperature, ensuring a stable draft and minimizing condensate formation, and it also guarantees a low temperature on the outer surface of the chimney, which is a key factor for fire safety.

The system is suitable for venting combustion products from heating appliances running on gas, liquid, and solid fuels. All elements are made from high-quality, certified materials, and the system itself complies with the European standard LVS EN-1856-1:2009 and is CE marked, confirming its reliability and adherence to the strict safety requirements of the European Union.

Main Installation Requirements:

- Overall Chimney Height: The minimum height of the chimney system from the appliance's grate to the flue gas outlet must be at least 5 meters.

- Structural Support: The chimney must be secured to load-bearing structures (walls, floors) using wall or joist brackets. The distance between supports should not exceed 2 meters. The maximum unsupported height of the chimney above the roof is 1.5 meters. If the height is greater, rigid guy wires must be installed.

- Fire Safety: When passing T450 and T600 class chimneys through floors, walls, or roofs made of combustible materials, a minimum clearance of 100 mm must be maintained from the outer wall of the chimney to these materials. The resulting space must be filled with heat-resistant, non-combustible insulation, such as rock wool.

- Joint Placement: It is not permitted to place joints between chimney elements inside walls, floors, or roof structures. The visible part of the insulated pipe in a room after passing through a floor must be at least 300 mm.

- Condensate Drainage and Maintenance: A condensate collection point (a tee with a drain or a base plate with a drain) must be provided at the base of the chimney. Easy access to inspection hatches must be ensured for system cleaning and maintenance.

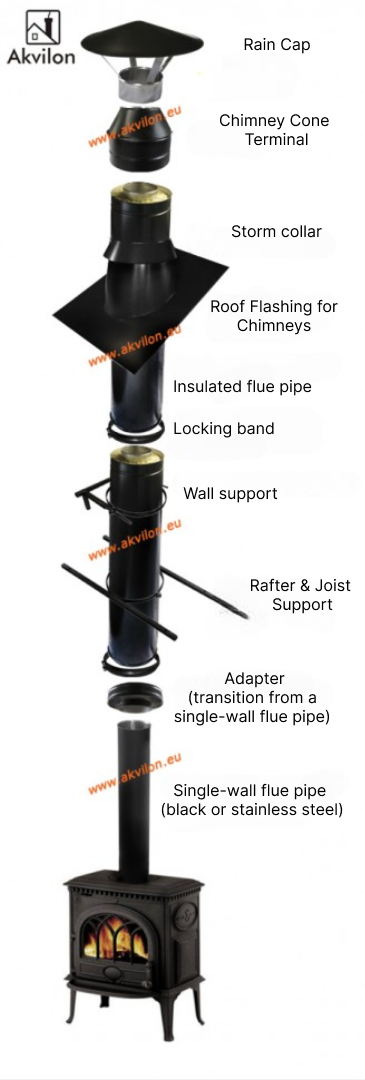

Installation Steps: Brief Description

- Starting the Installation: The chimney is installed from the bottom up. A wall support bracket or a floor support plate is used as the base. The first element is typically a tee with an inspection port and a condensate drain.

- Assembling Vertical Sections: The chimney elements are connected using a socket-and-spigot system. Vertical sections are assembled "with the condensate flow" (the upper element fits inside the lower one) to ensure that any moisture runs down the inner liner without leaking out. The assembly direction is indicated by arrows on the elements.

- Securing the Connections: Each joint is securely fastened with a special locking band. For chimneys with a diameter over 250 mm, in addition to locking bands, it is mandatory to use stainless steel rivets (6-16 per joint).

- Passing Through Floors and Walls: An opening is cut in the structures, maintaining the required 100 mm safety clearance. The space is filled with non-combustible insulation, and the opening is covered on both sides with decorative plates (rosettes).

- Passing Through the Roof: A special roof flashing is used to seal the roof penetration, with its angle chosen to match the roof's pitch. The penetration assembly is additionally insulated to a thickness of 100 mm. A storm collar is installed on the pipe above the flashing to prevent precipitation from entering the gap. The joint between the storm collar and the pipe is sealed with a roofing sealant.

- Finishing the Chimney: The installation is completed by fitting a cone, on top of which a chimney cap is mounted for protection from precipitation.

Installation Diagrams

Scheme 1. External Installation with Wall Mounting

This is the most common type of installation. The insulated chimney is attached to the external wall of the building using wall brackets.

- Connection to the Appliance: A 90° Tee-piece is used for the connection. The side outlet of the tee connects to the heating appliance, typically with a single-wall pipe via a special adapter that provides a transition from the insulated (twin-wall) chimney to a single-wall pipe.

- Inspection and Condensate Drainage: A removable condensate drain (A) is installed at the bottom of the tee-piece. This component also serves as a cleanout door for chimney inspection and cleaning.

- Wall Penetration: The opening in the wall through which the connecting pipe passes is covered with a decorative plate.

- Chimney Termination: The chimney is topped with a cone, which protects the insulation layer.

- Cleaning Options:

- A: Standard solution – through the removable condensate drain.

- B: A 90° Tee-piece with a dedicated cleanout door.

- C: A 90° Tee-piece with an inspection hatch opposite the appliance connection, which simplifies cleaning the horizontal section.

Scheme 2. External Installation Bypassing a Roof Overhang

This schematic is used when it is necessary to bypass a large roof overhang.

- Fixing and Offset: The chimney is secured to the wall with wall brackets. The offset to bypass the overhang is created using two 45° elbows and a straight pipe section between them.

- Connection and Inspection: A 90° Tee-piece with an inspection hatch opposite the inlet (A) is used to connect to the boiler. This allows for easy cleaning of both the vertical and horizontal sections. A condensate drain is installed at the bottom. A non-insulated 90° elbow is used for the direct connection to the heating appliance.

- Structural Stability: If the chimney height above the last fixing point exceeds 1.5 meters, rigid stays must be installed to ensure stability against wind loads.

- Termination and Decorative Elements: The chimney is terminated with a cone. The opening in the wall is covered with a decorative plate.

Scheme 3. External Installation with a Large Distance from the Wall

A solution for cases where the chimney needs to be positioned at a significant distance from the wall (e.g., to bypass a wide roof overhang without using elbows).

- Mounting: Extended wall brackets are used, providing a distance of up to 800 mm from the wall.

- Connection: If the heating appliance is located in a basement, for example, the connection can be made using a 45° Tee-piece in combination with a straight section and a 45° elbow. A condensate drain is installed at the bottom of the tee.

- Chimney Termination: A cone is installed at the top.

- Additional Cleaning: For easier maintenance, a 45° Tee-piece with an integrated cleanout door can be used.

Scheme 4. Internal Installation (for Saunas, Fireplaces, Stoves)

A typical solution for saunas, small fireplaces, and cast iron/metal stoves. The chimney runs inside the building through ceilings and the roof.

- Passing Through Structures: A floor support is used to secure the chimney to intermediate floors, and a rafter support is used for attachment to the rafters.

- Roof Penetration: A "roof flashing" kit with a storm collar is used for a weather-tight seal where the chimney passes through the roof.

- Stability: If the chimney extends more than 1.5 m above the roof, rigid stays must be installed.

- Termination and Protection: The chimney is terminated with a cone. A rain cap can be added for extra protection against precipitation.

- Decorative Finish: The opening in the ceiling is covered with a two-part decorative plate.

- Appliance Connection: The section from the heating appliance to the main chimney can be insulated (B), non-insulated (C), or insulated with an offset (A), always observing the required fire-safety clearances.

- Adjustment and Compatibility: A damper is used to regulate the draft. A reducer is used to match the chimney diameter to the appliance outlet.

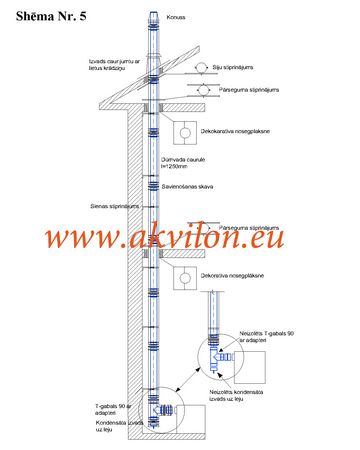

Scheme 5. Internal Installation with Wall Mounting

This scheme is similar to Scheme 1, but the chimney is installed inside the building.

- Installation: The chimney is attached to an internal wall and floor structures and passes through the roof.

- Connection: An insulated or non-insulated 90° Tee-piece with a condensate drain is installed at the bottom.

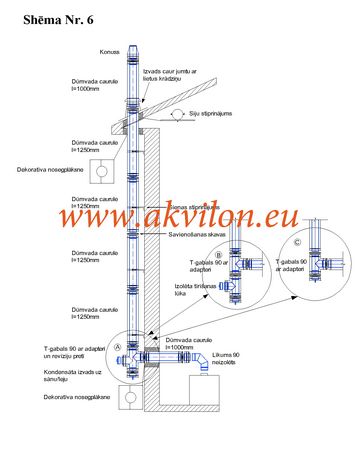

Scheme 6. Internal Installation Passing Through a Roof Overhang

Similar to Scheme 2, but the chimney passes directly through the roof overhang.

- Installation: A roof flashing with a storm collar is used for the penetration. A rafter support is used to fix the pipe to the rafters.

- Decorative Finish: The opening in the ceiling or soffit is covered with a decorative plate.

- Cleaning: As in Scheme 1, cleaning can be performed in three different ways.

Technical Documentation

All products are certified, CE marked, and comply with the mandatory LVS EN-1856-1:2009 standard.

Go to the main section with all certificates →

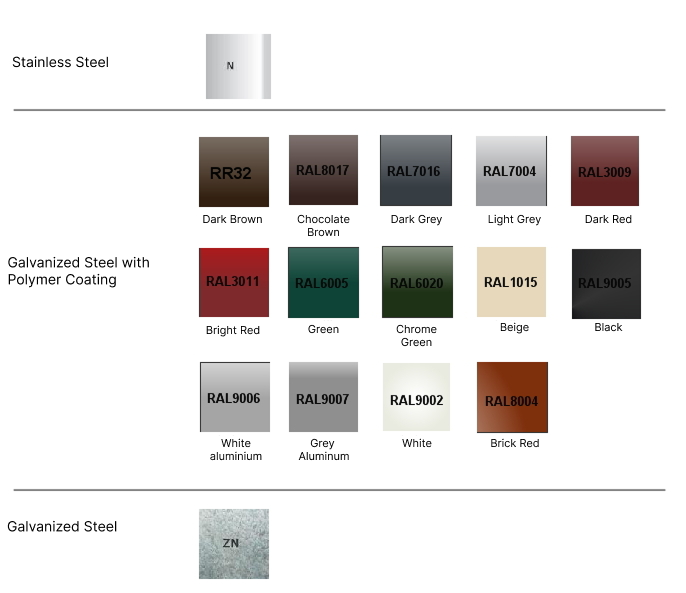

Outer Casing Options:

Standard IZOKOMPAKT Series

The outer casing can be made of stainless steel, galvanized steel, or painted steel (any color from the RAL catalog).

NORDIC PIPE Premium Version

For this series, high-quality galvanized steel (DX51+Z275) is used as the base, which is finished with a durable matte black powder coating. This option is ideal for modern interiors and exteriors.

Warranty Conditions

The manufacturer provides a 2-year warranty on its products, which is valid if the following key conditions are met:

- Installation, maintenance, and transportation are carried out in strict accordance with the instructions from SIA "AKVILON" and current building codes.

- The chimney is connected to a CE-certified heating appliance.

- The operating rules of the heating appliance are followed, appropriate fuel for the chimney is used, and the maximum operating temperature is not exceeded.

- Regular chimney cleaning is performed.

- There have been no unauthorized repairs or modifications to the chimney's structure.

Ready to order or need a consultation?

As a manufacturer, we offer the best prices and professional assistance in selecting the right chimney system for your project.

Get a Consultation Go to the Online Store |